Standout Projects

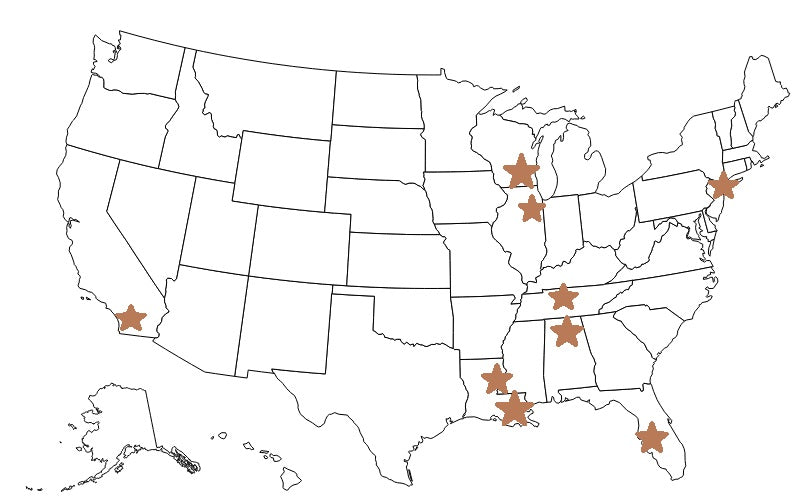

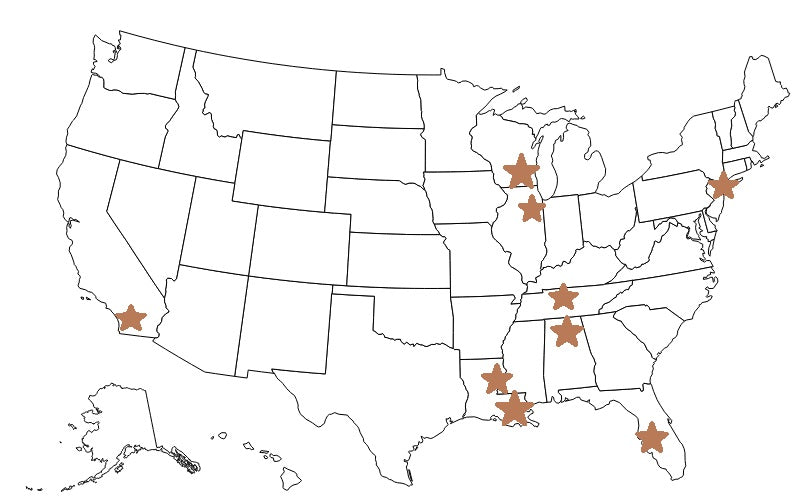

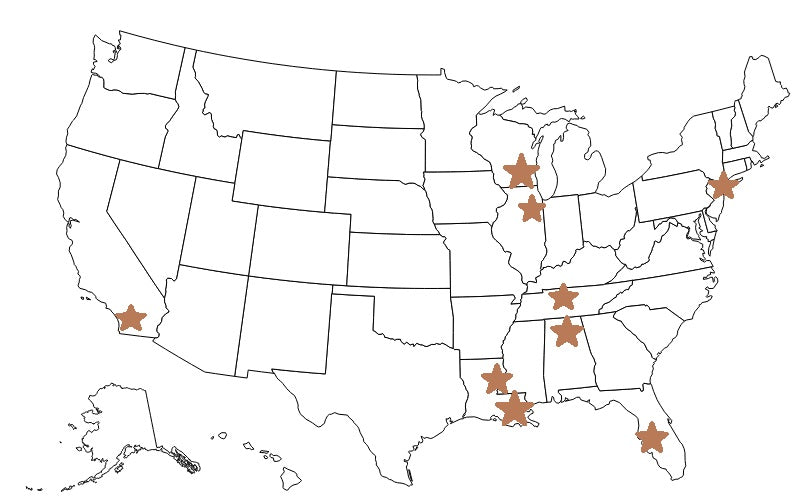

Thermal Remediation of Petroleum Hydrocarbons

The Defense Logistics Agency (DLA) commissioned in-situ thermal remediation clean up at eight of the bulk field constructed underground storage tanks (BFCUSTs). The following BFCUSTs were treated with their corresponding thermal technology: 4,15,20 with steam enhanced extraction and 1, 3, 5, 7, 11, 12 with electrical resistance heating. DLA selected MK to engineer and provide the equipment for two separate treatment systems to run simultaneously, one treatment system for the steam enhanced extraction remediation and one for the electrical resistance heating remediation. Both treatment systems utilized dual-phased treatment with a 2,000 and 3,000 CFM thermal oxidizer and multi-step liquid phase treatment, including but not limited to chemical injection, dissolved air floatation, media filtration, and air stripping. Over 7 years, MK’s thermal treatment systems have successfully removed 1.7 million pounds of Hydrocarbons from nine BFCUSTs.

Vinyl Chloride and Hydrocarbon Pump and Treat System

On February 3, 2023, one of the worst train derailments in modern history occurred in East Palestine, Ohio. 38 cars derailed and burned for multiple days; residents were forced to evacuate for a one-mile radius.

Within days of the incident, MK Environmental was contacted about potential water and air treatment equipment to help with mitigation and cleanup. MK was able to deliver a 100 GPM vinyl chloride water treatment system in less than 2 weeks after the request for equipment. Additionally, MK had a second 100 GPM water treatment system and a 1000 CFM vapor treatment system on standby per client request.

This project was possible and successful due to MK's large fleet of equipment that is ready for use and the clients' trust and experience with MK from previous projects.

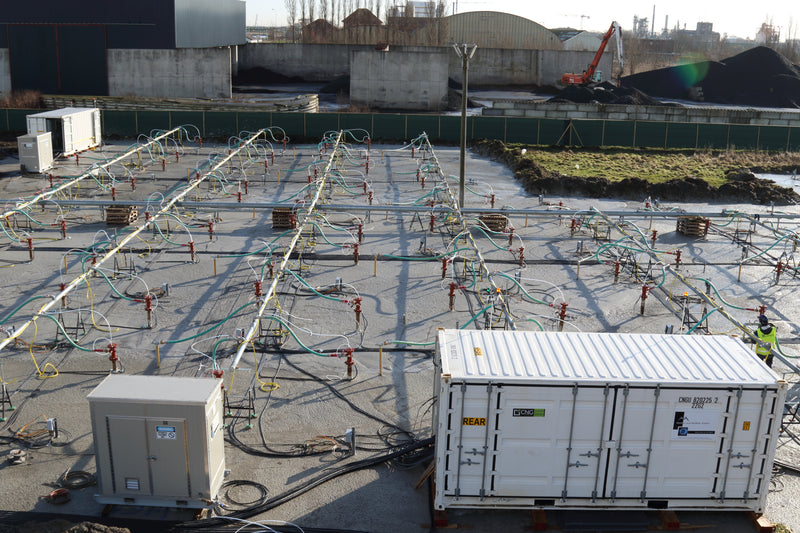

Coal Combustion Residuals

Facing environmental risks from toxic coal ash, the EPA’s 2015 regulations mandated rigorous groundwater testing and remediation. A coal-fired power plant enlisted MK to design an innovative cleanup for coal combustion residuals (CCR). Instead of excavating vast ash fields, MK’s sustainable approach treats contaminated groundwater by precipitating hazardous contaminants, minimizing environmental disturbance while recovering boron—a valuable industrial resource used in glass manufacturing and agriculture. Precise pH balance was critical, requiring HCl and NaOH, which posed safety and durability challenges. To combat corrosion from chemical vapors, MK engineered specialized plastic skids, ensuring longevity and operational safety. Their breakthrough technique integrates environmental protection with economic opportunity, offering a cost-effective, sustainable remediation model. This innovation enhances water quality and repurposes waste.

Project 1

Project Name

Project Name

Project Name

Project Name

Project Name